Asia Pacific Emulsion Polymer Market Size and Research

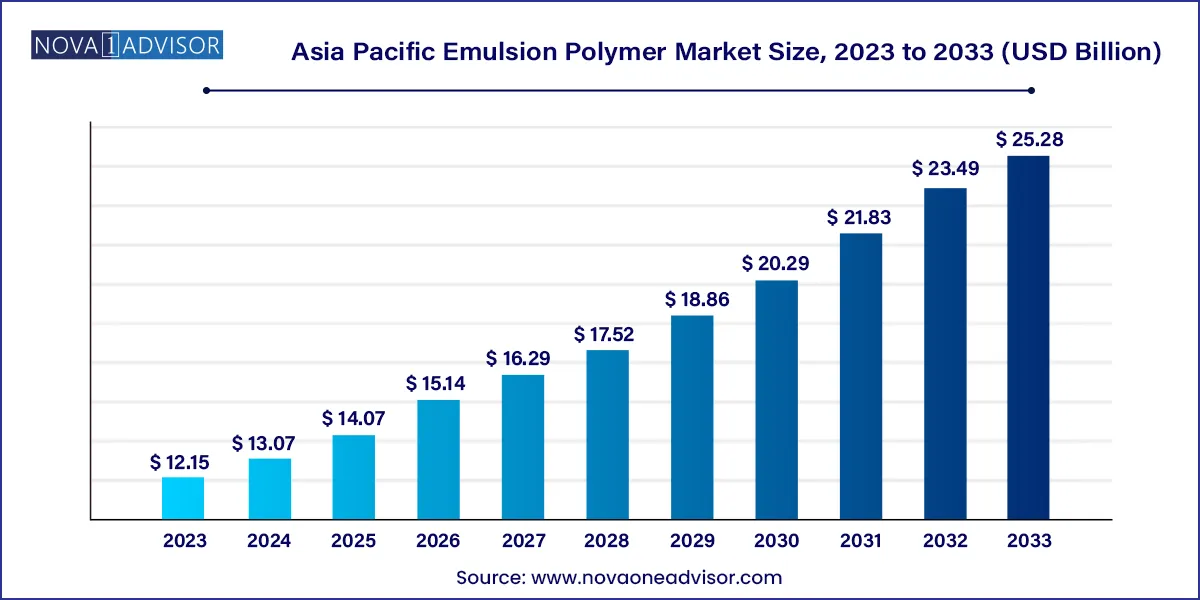

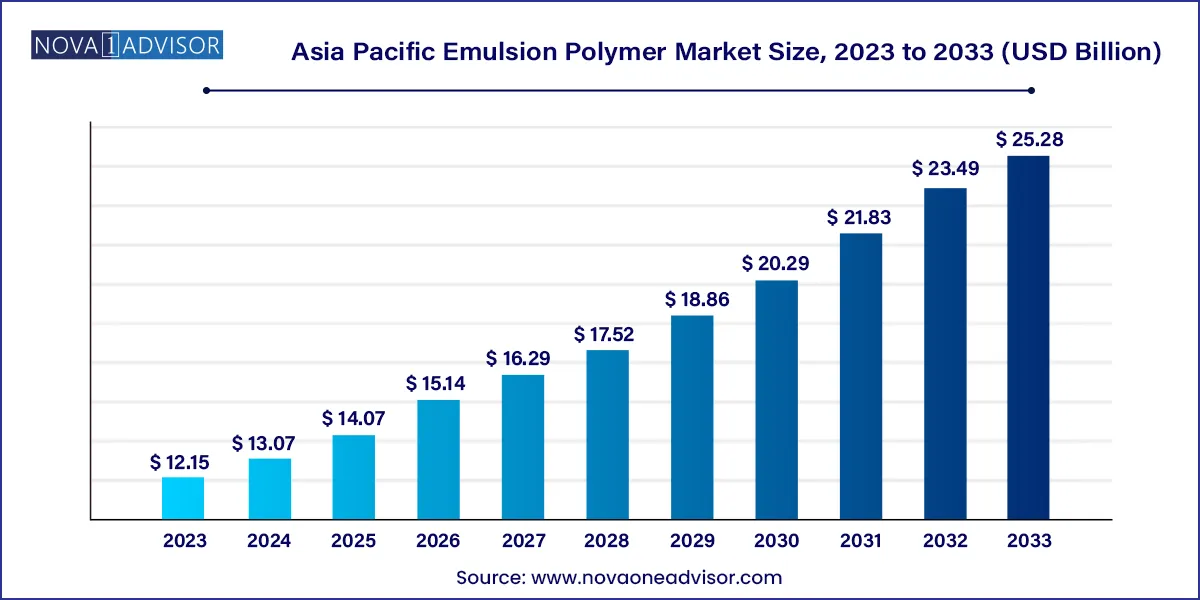

The Asia Pacific emulsion polymer market size was exhibited at USD 12.15 billion in 2023 and is projected to hit around USD 25.28 billion by 2033, growing at a CAGR of 7.6% during the forecast period 2024 to 2033.

Asia Pacific Emulsion Polymer Market Key Takeaways:

- The paints & coatings segment accounted for a revenue share of 45.7% in 2023.

- The building & construction segment led the market, accounting for a revenue share of 37.7% in 2023.

- Paper and paperboard coatings application segment accounted for a significant market share in 2023.

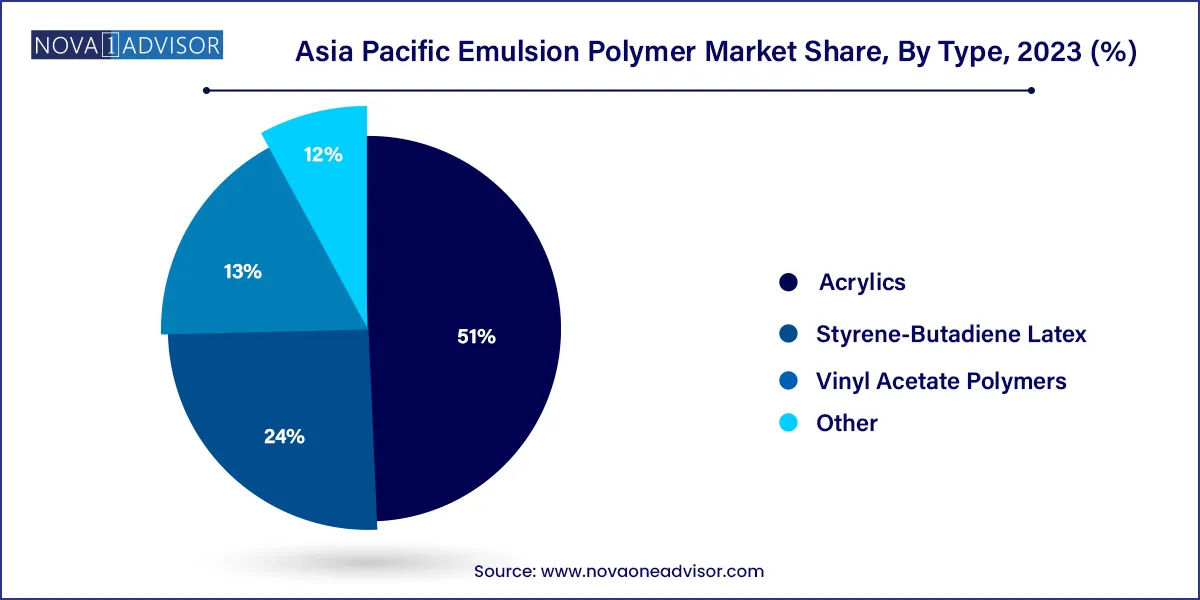

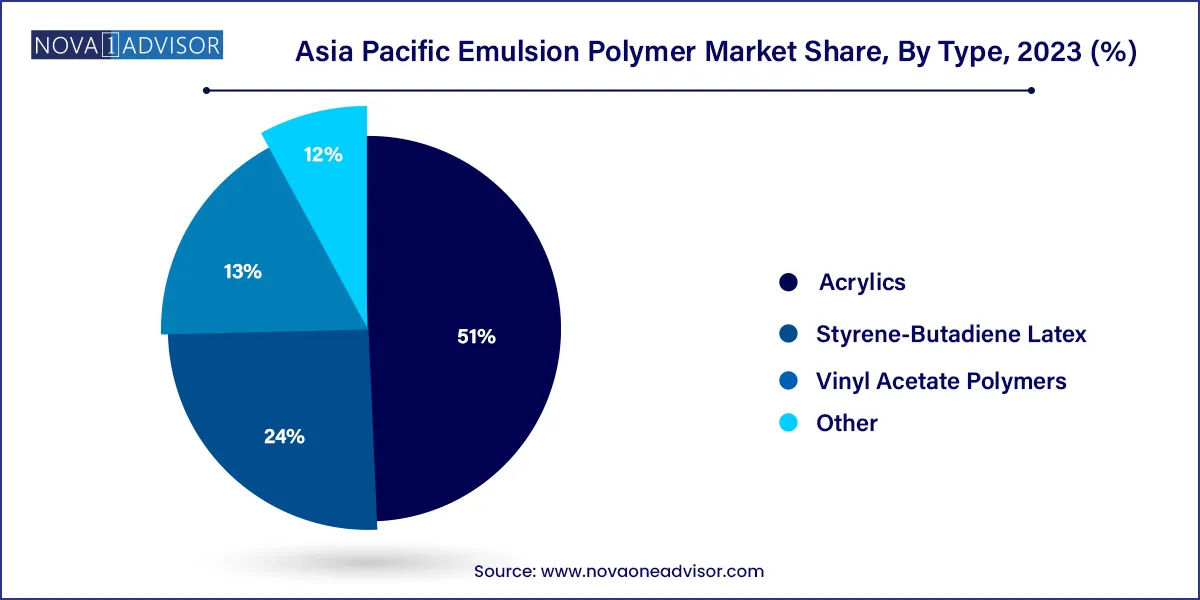

- Acrylics polymer dominated the market, accounting for a share of 51.0% in 2023.

- Styrene butadiene latex emerged as the second largest type segment in 2023.

Market Overview

The Asia Pacific Emulsion Polymer Market is a robust and rapidly expanding segment of the global chemicals industry, driven by the region’s manufacturing dynamism, infrastructural growth, and innovation in water-based polymer technologies. Emulsion polymers are synthesized via emulsion polymerization, typically in water, making them environmentally friendly, cost-effective, and versatile. These polymers form the backbone of countless formulations, from paints and coatings to adhesives, sealants, and textiles, thanks to their excellent binding, film-forming, and durability-enhancing properties.

In Asia Pacific, the demand for emulsion polymers is deeply influenced by megatrends such as urbanization, green building mandates, rising automotive production, and a strong shift toward sustainable, water-based solutions. The region hosts several of the world’s fastest-growing economies most notably China, India, Southeast Asia, and Vietnam all of which are aggressively investing in infrastructure, residential housing, and industrial manufacturing.

The market features a wide variety of emulsion polymer types including acrylics, styrene-butadiene latex, and vinyl acetate polymers, each tailored for unique end-user needs. Water-based paints made with emulsion polymers are widely adopted in the construction and automotive industries for their low VOC emissions, weather resistance, and superior finish quality. Additionally, the paper and packaging industries rely on emulsion polymers for their barrier properties and printability.

The Asia Pacific region benefits from abundant raw material availability, low production costs, and rising domestic demand, making it a hub for both manufacturing and consumption. Strategic investments in R&D, capacity expansions, and sustainable chemistry initiatives are reshaping the competitive landscape of the emulsion polymer market in the region.

Major Trends in the Market

-

Shift Toward Environmentally Sustainable Products: The growing demand for water-based, low-VOC polymers is replacing solvent-based alternatives, especially in paints and coatings.

-

Rapid Growth in Construction and Infrastructure: Urbanization and smart city development across India, China, and Southeast Asia are spurring the use of emulsion polymers in building materials.

-

Technological Advancements in Polymerization Techniques: Innovations like core-shell polymerization and mini-emulsion techniques are enhancing performance, stability, and cost-effectiveness.

-

Boom in Adhesives and Packaging Applications: Increased e-commerce and flexible packaging demand are leading to wider adoption of emulsion polymer adhesives.

-

Surging Automotive Manufacturing and Aftermarket: Emulsion polymers are being used in vehicle paints, protective coatings, and interiors, supporting high gloss, scratch resistance, and thermal stability.

-

Growth of Bio-based and Renewable Emulsion Polymers: Biopolymer research is leading to a new generation of renewable-content emulsion polymers in response to regulatory and consumer pressure.

Report Scope of Asia Pacific Emulsion Polymer Market

| Report Coverage |

Details |

| Market Size in 2024 |

USD 13.07 Billion |

| Market Size by 2033 |

USD 25.28 Billion |

| Growth Rate From 2024 to 2033 |

CAGR of 7.6% |

| Base Year |

2023 |

| Forecast Period |

2024-2033 |

| Segments Covered |

Type, Application, End-use, Country |

| Market Analysis (Terms Used) |

Value (US$ Million/Billion) or (Volume/Units) |

| Country scope |

China; India; Japan; South Korea; Australia; Southeast Asia |

| Key Companies Profiled |

OMNOVA Solutions; Trinseo; Synthomer Plc; DIC Corporation; JSR Corporation; Solutions; Dairen Chemical Corporation; Nova Polychem;Kamsons Chemicals Pvt. Ltd.; Arkema Group.; Asahi Kasei Corporation; Apcotex Industries Ltd.; Sumitomo Chemical |

Key Market Driver: Rising Demand from Construction and Infrastructure Development

One of the most significant drivers in the Asia Pacific emulsion polymer market is the unrelenting demand from the construction and infrastructure sectors. Across countries like China, India, and Vietnam, public and private investments are heavily directed toward urban housing, highways, rail networks, airports, and commercial buildings.

Emulsion polymers play a critical role in these applications, particularly through their use in architectural coatings, concrete additives, waterproof membranes, and sealants. The water-based nature of these polymers aligns well with green building codes and LEED certifications, which are gaining importance in Asia’s construction practices.

For instance, emulsion-based acrylic binders are widely used in paints due to their excellent adhesion, weather resistance, and ease of application. In rapidly urbanizing cities like Mumbai, Jakarta, and Chengdu, the surge in mid-income housing construction is directly translating into increased consumption of emulsion-polymer-based coatings and adhesives.

Key Market Restraint: Volatility in Raw Material Prices and Supply Chain Disruptions

Despite its strong growth trajectory, the emulsion polymer market in Asia Pacific faces a significant restraint in the form of fluctuating raw material prices and logistical challenges. The production of emulsion polymers relies on monomers such as styrene, butadiene, acrylic acid, and vinyl acetate, most of which are derivatives of crude oil or natural gas.

This dependence makes emulsion polymer prices sensitive to global oil price volatility, geopolitical instability, and supply disruptions caused by trade tensions or natural calamities. For example, during the COVID-19 pandemic and the Russia-Ukraine conflict, the global supply of butadiene and ethylene faced bottlenecks, impacting polymer production in Asia.

Additionally, environmental regulations on styrene production and VOC emissions are tightening in China and South Korea, leading to potential supply constraints. These factors make cost forecasting difficult and affect profit margins for both producers and downstream industries like paint manufacturers and adhesive formulators.

Key Market Opportunity: Expansion of Water-based Coatings in Asia’s Automotive and Textile Industries

An emerging opportunity in the Asia Pacific emulsion polymer market lies in the expanding use of water-based coatings in the automotive and textile sectors, driven by both regulatory compliance and technological advancements.

As OEMs shift from solvent-based to water-based paint systems to meet carbon neutrality goals and VOC regulations, emulsion polymers especially acrylics and PU dispersions are increasingly used in automotive basecoats, clearcoats, and underbody protection layers. This transition is especially pronounced in China and India, where domestic automakers are upgrading their painting technologies.

Meanwhile, the textile and apparel industries are moving toward eco-friendly finishes, water-repellent coatings, and dye-fixing systems. Emulsion polymers offer ideal performance characteristics such as wash durability, soft hand feel, and fabric breathability, making them suitable for high-performance textile applications.

The convergence of sustainability, consumer demand for non-toxic finishes, and advancements in polymer chemistry positions emulsion polymers as central to the next generation of eco-friendly industrial applications in Asia.

Asia Pacific Emulsion Polymer Market By Application Insights

Paints and coatings lead the application segment, driven by Asia Pacific’s massive construction activities and decorative painting markets. Emulsion polymers are key binders that enhance adhesion, sheen, and scrub resistance. Increasing urban infrastructure and interior refurbishing activities in tier 2 and tier 3 cities of countries like India and the Philippines are fueling this demand.

Adhesives and sealants are the fastest-growing application, benefiting from booming packaging, e-commerce, and furniture sectors. Waterborne adhesives based on vinyl acetate and styrene-acrylate emulsions offer high bond strength and safety in consumer applications. Emerging demand for label adhesives, construction sealants, and hygiene product bonding is boosting consumption, especially in Malaysia and Vietnam.

Asia Pacific Emulsion Polymer Market By End use Insights

Building and construction is the dominant end-use industry, as Asia Pacific accounts for nearly 60% of global construction activity growth. From insulation systems and waterproofing to tiling and wood coatings, emulsion polymers play a pivotal role in performance enhancement and longevity. Moreover, government schemes like Smart Cities (India) and China’s Belt and Road Initiative are creating long-term demand across public infrastructure, commercial real estate, and housing.

Textile and coatings are the fastest-growing end-use segments, largely due to the shift toward functional textiles, smart apparel, and non-woven fabric manufacturing. Emulsion polymers are used to impart hydrophobicity, dye fastness, anti-pilling, and crease resistance to fabrics. As textile hubs in Bangladesh, Indonesia, and India adopt sustainable finishing technologies, demand for water-based polymers is surging.

Asia Pacific Emulsion Polymer Market By Type Insights

Acrylics dominate the emulsion polymer type segment, thanks to their broad application scope, UV resistance, and compatibility with waterborne formulations. Acrylic-based emulsions are extensively used in paints, construction chemicals, adhesives, and textile finishing agents. In particular, self-crosslinking and styrene-acrylic emulsions offer excellent durability and flexibility, making them ideal for exterior paints in humid and high-temperature regions of Asia.

Meanwhile, Styrene-Butadiene Latex (SBL) is emerging as the fastest-growing segment. It is widely used in carpet backings, paper coatings, and pressure-sensitive adhesives. The material offers excellent water resistance and elasticity, which is increasingly required in packaging and hygiene products. As paperless office trends give way to food-safe, printed packaging growth, demand for SBL is gaining renewed traction, especially in China, Japan, and South Korea.

Country Insights

China

China dominates the Asia Pacific emulsion polymer market, driven by its massive construction sector, leading position in paint and coatings production, and advanced manufacturing capabilities. The Chinese government’s push for green building practices and energy-efficient materials has accelerated the replacement of solvent-based coatings with emulsion-based alternatives.

Chinese manufacturers like Wanhua Chemical and Sinopec are at the forefront of polymer R&D, producing high-performance emulsion polymers tailored for diverse applications. Moreover, increasing exports of textiles, home furnishings, and automotive parts is fueling domestic consumption of emulsion polymers for functional coatings and adhesives.

India

India is the fastest-growing market in the region, thanks to booming construction, rising automobile production, and an expanding middle class driving consumer goods consumption. The government's infrastructure schemes, such as PMAY and Bharatmala, are spurring demand for paints, adhesives, and construction chemicals.

The Indian market is also witnessing rapid penetration of eco-friendly emulsion paints, driven by rising awareness, climatic adaptability, and regulatory support. Additionally, domestic chemical manufacturers are collaborating with global players to set up local emulsion polymer plants, reducing import dependency and boosting product availability.

Japan, South Korea, Southeast Asia, and Australia

-

Japan focuses on high-end applications such as electronic adhesives, UV-cured coatings, and medical-grade emulsions, with strict environmental standards governing formulation practices.

-

South Korea’s automotive and packaging industries drive demand for specialty emulsion polymers with superior thermal resistance and clarity.

-

Southeast Asia (Vietnam, Thailand, Indonesia) is emerging as a production hub for paints, textiles, and flexible packaging, aided by lower labor costs and FDI in manufacturing.

-

Australia represents a stable and mature market with demand concentrated in premium building products and advanced textile coatings.

Some of the prominent players in the Asia Pacific emulsion polymer market include:

- OMNOVA Solutions

- Synthomer Plc

- Trinseo

- DIC Corporation

- Arkema

- Asahi Kasei Corporation

- JSR Corporation

- Dairen Chemical Corporation

- Nova Polychem

- Kamsons Chemicals Pvt. Ltd.

- Apcotex Industries Ltd.

- Sumitomo Chemical

Segments Covered in the Report

This report forecasts revenue growth at country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2021 to 2033. For this study, Nova one advisor, Inc. has segmented the Asia Pacific emulsion polymer market

Type

- Acrylics

- Styrene-Butadiene Latex

- Vinyl Acetate Polymers

- Other

Application

- Paints and Coatings

- Adhesives & Sealants

- Paper & Paperboard

- Others

End-use

- Building & Construction

- Automotive

- Chemicals

- Textile & Coatings

- Others

Country

- China

- India

- Japan

- South Korea

- Australia

- Southeast Asia