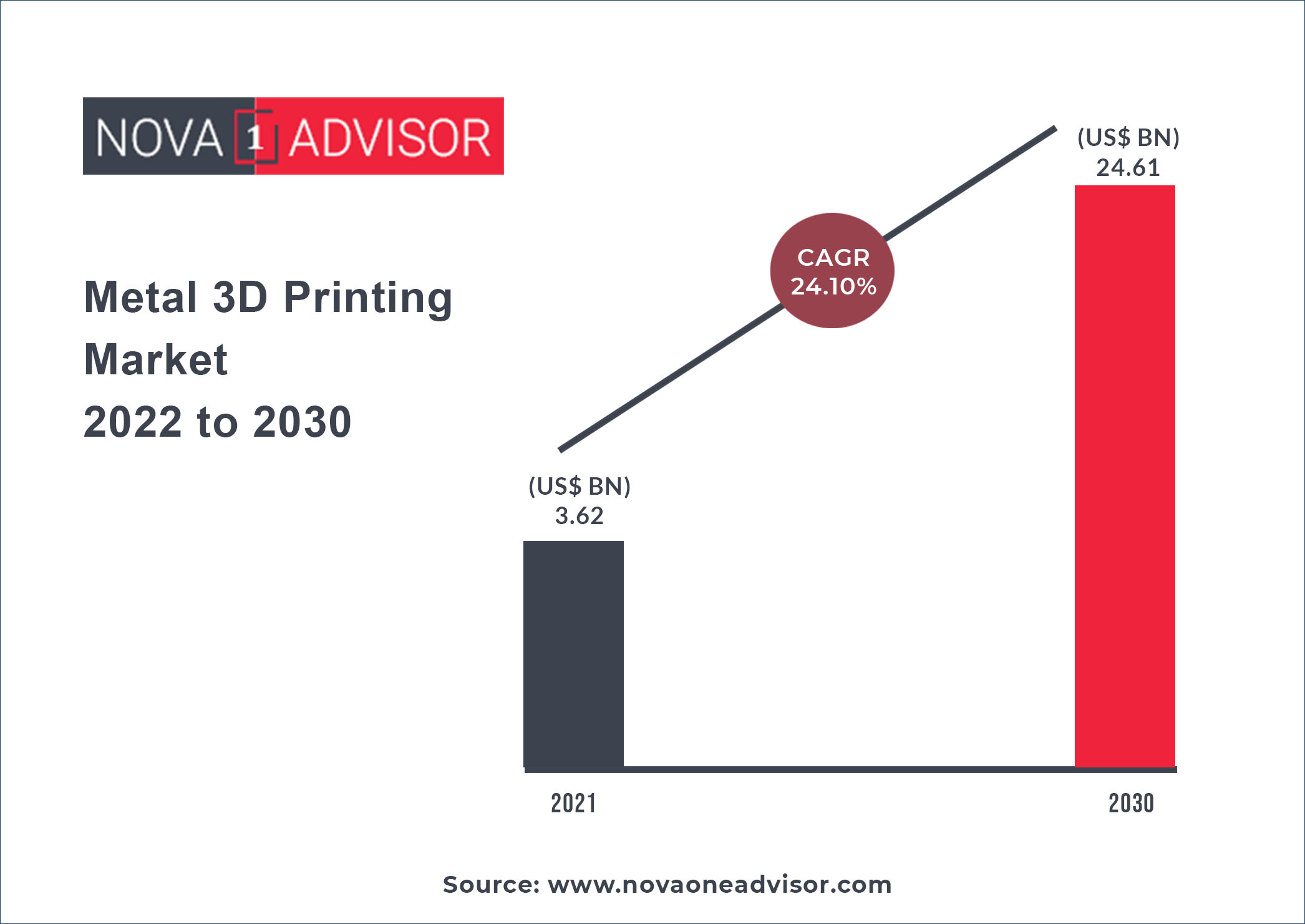

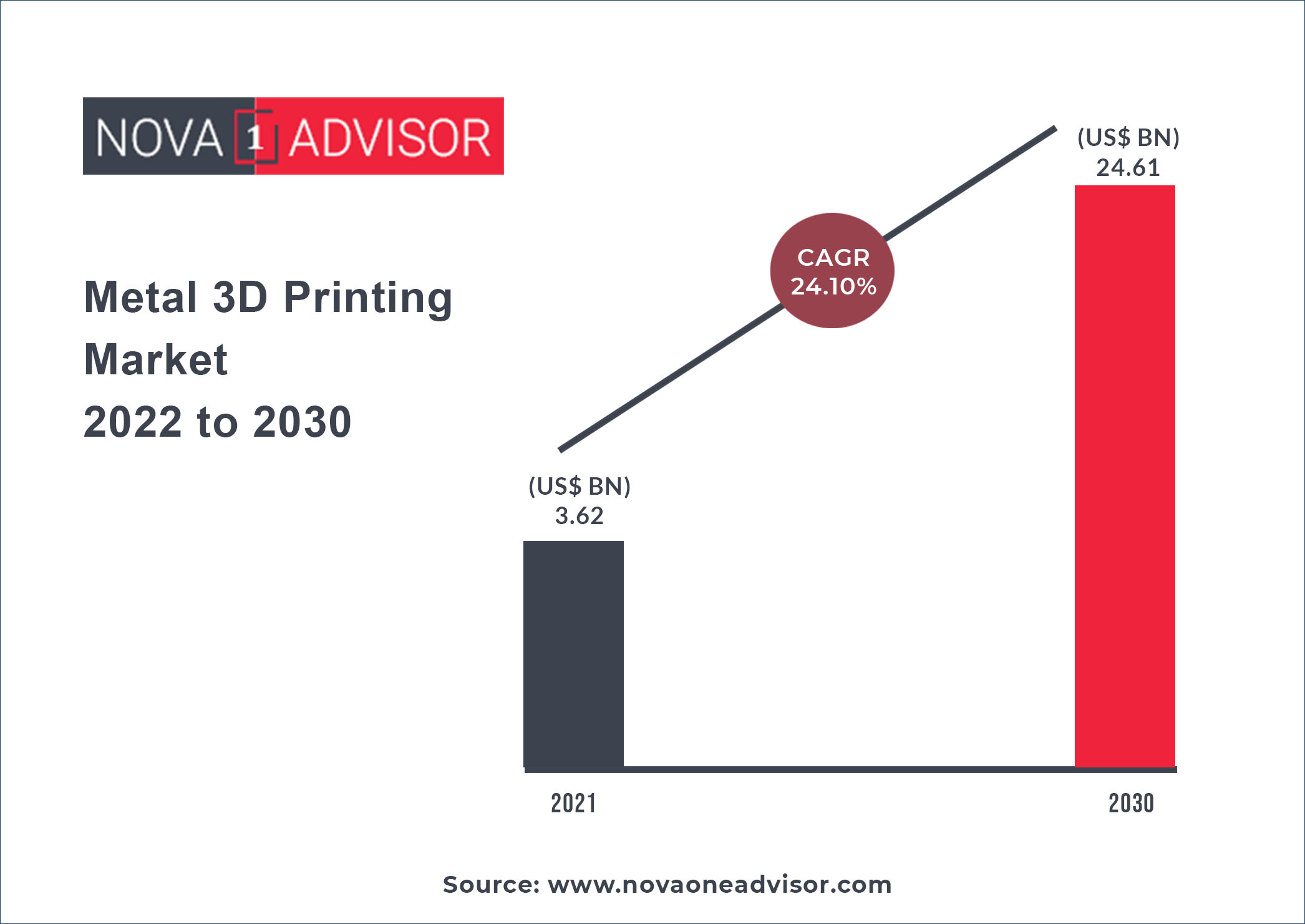

The global Metal 3D Printing market gathered revenue around USD 3.62 billion in 2021 and market is set to grow USD 24.61 billion by the end of 2030 and is estimated to expand at a modest CAGR of 24.1% during the prediction period 2022 to 2030.

Growth Factors:

Metal 3D printing is one such market that has benefitted significantly from the growing necessity of rapid prototyping and advanced manufacturing practices. The industry is poised to witness unprecedented growth over the forecast period owing to the rising application of additive manufacturing in various industry verticals. The global industrial printer market is increasingly advancing towards consolidation to stay ahead of the competition. A substantial growth factor for this market is increasing innovation, which is leading to several benefits through the adoption of metal 3D printing across heavy industry applications.

Increasing adoption of metal 3D printers for the designing and prototyping of products and objects, coupled with the reduced manufacturing expenditure and accuracy in the end product, is a key market proliferating factor. The market is poised to witness high demand arising prominently from the healthcare, automotive, aerospace and defense sectors. Growing advancements in the healthcare sector so as to curb physical disabilities and ensure healthy living are influencing the sector to flourish and adopt new innovative methodologies, such as 3D printing. Additionally, the automotive and aerospace sectors, where prototyping and designing play a vital role in research & development so as to achieve perfection in their production are leading towards greater opportunities and increasing the adoption of the 3D printing process.

Report Coverage

| Report Scope |

Details |

| Market Size |

USD 24.61 billion by 2030 |

| Growth Rate |

CAGR of 24.1% From 2022 to 2030 |

| Base Year |

2021 |

| Forecast Period |

2022 to 2030 |

| Report coverage |

Growth Factors, Revenue Status, Competitive Landscape, and Future Trends |

| Segments Covered |

Component, technology, software, application, vertical, Region

|

| Regional Scope |

North America, Europe, Asia Pacific, Latin America, Middle East & Africa (MEA) |

| Companies Mentioned |

Materialise NV; 3D Systems, Inc.; GE Additive; Autodesk Inc.; Optomec, Inc..

|

Technology Insights

Selective Laser Melting (SLM) technology led the market and accounted for more than 20.0% share of the global revenue in 2021. Although the advantages and ease of operations associated with the SLM technology are encouraging the adoption of this technology, advances in technology and aggressive research and development activities undertaken by the industry experts and researchers are opening opportunities for several other efficient and reliable technologies. Other technologies used for metal 3D printing include Selective Laser Sintering (SLS), Direct Metal Laser Sintering (DMLS), Inkjet printing, Electron Beam Melting (EBM), Laser Metal Deposition (LMD), Laminated Object Manufacturing (LOM), and Electron-beam Freeform Fabrication (EBF3).

EBM accounted for a considerable revenue share in 2021 owing to the extensive adoption of the technology across various metal 3DP processes. The DMLS, EBF3, and SLS are expected to witness high adoption over the forecast period as these technologies are applicable in specialized additive manufacturing processes. Growing demand from aerospace and defense, healthcare, and automotive verticals would open opportunities for the adoption of these technologies.

Software Insights

Design software led the market and accounted for more than 35.0% share of the global revenue in 2021. Design software is used for constructing the designs of the object to be printed, particularly in automotive, aerospace and defense, and construction and engineering verticals. Design software acts as a bridge between the objects to be printed and the printer’s hardware.

The scanning software segment is expected to expand at the highest CAGR of 17.4% from 2022 to 2030 and generate considerable revenue over the forecast period in line with the growing adoption of scanners. The demand for scanning software is estimated to grow on account of the growing trend of scanning objects and storing scanned documents. This ability to store the scanned images of the objects irrespective of their size or dimensions for the 3-dimensional printing of these objects whenever necessary is expected to fuel the growth of the scanner software segment over the forecast period.

Application Insights

The prototyping segment led the market and accounted for more than 55.0% share of the global revenue in 2021 due to the extensive adoption of the prototyping process across several industry verticals. The automotive and aerospace and defense verticals particularly use prototyping to design and develop parts, components, and complex systems precisely. Prototyping allows manufacturers to achieve higher accuracy and develop reliable end products. Hence, the prototyping segment is expected to continue dominating the market over the forecast period.

Functional parts include smaller joints and other metallic hardware connecting components. The accuracy and precise sizing of these functional parts are of paramount importance while developing machinery and systems. The functional parts segment is expected to expand at a significant CAGR of 24.0% from 2022 to 2030 in line with the increasing demand for designing and building functional parts.

Component Insights

The hardware segment led the market and accounted for more than 60.0% share of the global revenue in 2021. The hardware segment is anticipated to maintain its lead over the forecast period. The metal 3D printing hardware component segment is bifurcated by technology and application. Similarly, the software segment is further categorized by design software, inspection software, printer software, and scanning software.

The services segment is expected to expand at a significant CAGR of 23.5% from 2022 to 2030. With the adoption of methodology, metal 3D printing services help manufacturers to produce complicated and delicate functional parts with greater ease and accuracy. Moreover, the production expenditures are being reduced significantly owing to the enhanced prototyping and benefits offered by the technology. As such, the benefits and advantages of 3D printing are gaining greater attention from the players of various industry verticals.

Vertical Insights

The automotive segment led the market and accounted for more than 20.0% share of the global revenue in 2021. Other verticals include aerospace and defense, healthcare, consumer electronics, industrial, power, and energy, among others. The aerospace and defense, healthcare, and automotive verticals are anticipated to contribute significantly to the growth of metal 3D printing over the forecast period owing to the active adoption of technology in various production processes associated with these verticals.

The healthcare segment is expected to expand at a significant CAGR of 24.2% from 2022 to 2030. In the healthcare sector, additive manufacturing helps in the development of artificial tissues and muscles, which replicate the natural human tissues and can be used in replacement surgeries. These capabilities are expected to help in driving the adoption of metal 3D printing across the healthcare vertical and contribute significantly towards the growth of the industrial segment.

Regional Insights

North America dominated the market and accounted for over 30.0% share of the global revenue in 2021 owing to the extensive adoption of additive manufacturing in the region. North American countries such as the U.S. and Canada have been among the prominent and early adopters of these technologies in various manufacturing processes. The regional market is offering lucrative opportunities for metal 3D printing in different applications. Europe happens to be the largest region in terms of its geographical footprint. It is home to several additive manufacturing industry players, which hold strong technical expertise in additive manufacturing processes. Hence, the European market happens to be the second largest.

Asia Pacific is projected to expand at the highest CAGR over the forecast period. This rapid adoption of metal 3D printing in Asia Pacific can be attributed to the developments and upgrades across the manufacturing industry within the region. The Asia Pacific region is also emerging as a manufacturing hub for the automotive and healthcare industries. A stronghold on the production of consumer electronics, coupled with rapid urbanization, is also contributing to the rising demand for three-dimensional printing in the region.

Competitive Rivalry

Foremost players in the market are attentive on adopting corporation strategies to enhance their market share. Some of the prominent tactics undertaken by leading market participants in order to sustain the fierce market completion include collaborations, acquisitions, substantial spending in R&D and the improvement of new-fangled products or reforms among others.

Major manufacturers & their revenues, percentage splits, market shares, growth rates and breakdowns of the product markets are determined through secondary sources and verified through the primary sources.

- Company Overview

- Company Market Share/Positioning Analysis

- Product Offerings

- Financial Performance

- Recent Initiatives

- Key Strategies Adopted by Players

- Vendor Landscape

- List of Suppliers

- List of Buyers

Some of the prominent players in the Metal 3D Printing Market include:

- Materialise NV

- 3D Systems, Inc.

- GE Additive

- Autodesk Inc.

- Optomec, Inc.

Segments Covered in the Report

This research report offers market revenue, sales volume, production assessment and prognoses by classifying it on the basis of various aspects. Further, this research study investigates market size, production, consumption and its development trends at global, regional, and country level for the period of 2017 to 2030 and covers subsequent region in its scope:

- Hardware

- Software

- Services

- By Technology

- Selective Laser Sintering

- Direct Metal Laser Sintering

- Inkjet Printing

- Electron Beam Melting

- Laser Metal Deposition

- Laminated Object Manufacturing

- Electron Beam Freeform Fabrication

- Selective Laser Melting

- By Software

- Design Software

- Inspection Software

- Printer Software

- Scanning Software

- By Application

- Prototyping

- Tooling

- Functional Parts

- By Vertical

- Automotive

- Aerospace & Defense

- Healthcare

- Consumer Electronics

- Power & Energy

- Others

By Geography

North America

Europe

- Germany

- France

- United Kingdom

- Rest of Europe

Asia Pacific

- China

- Japan

- India

- Southeast Asia

- Rest of Asia Pacific

Latin America

- Brazil

- Rest of Latin America

Middle East & Africa (MEA)

- GCC

- North Africa

- South Africa

- Rest of Middle East & Africa

Research Methodology

In the study, a unique research methodology is utilized to conduct extensive research on the growth of the Metal 3D Printing market, and reach conclusions on the future growth parameters of the market. This research methodology is a combination of primary and secondary research, which helps analysts ensure the accuracy and reliability of the conclusions.

Secondary resources referred to by analysts during the production of the Metal 3D Printing market study are as follows - statistics from government organizations, trade journals, white papers, and internal and external proprietary databases. Analysts have also interviewed senior managers, product portfolio managers, CEOs, VPs, marketing/product managers, and market intelligence managers, all of whom have contributed to the development of this report as a primary resource.

Comprehensive information acquired from primary and secondary resources acts as a validation from companies in the market, and makes the projections on the growth prospects of the Metal 3D Printing markets more accurate and reliable.

Secondary Research

It involves company databases such as Hoover's: This assists us recognize financial information, structure of the market participants and industry competitive landscape.

The secondary research sources referred in the process are as follows:

- Governmental bodies, and organizations creating economic policies

- National and international social welfare institutions

- Company websites, financial reports and SEC filings, broker and investor reports

- Related patent and regulatory databases

- Statistical databases and market reports

- Corporate Presentations, news, press release, and specification sheet of Manufacturers

Primary Research

Primary research includes face-to face interviews, online surveys, and telephonic interviews.

- Means of primary research: Email interactions, telephonic discussions and Questionnaire based research etc.

- In order to validate our research findings and analysis we conduct primary interviews of key industry participants. Insights from primary respondents help in validating the secondary research findings. It also develops Research Team’s expertise and market understanding.

Industry participants involved in this research study include:

- CEOs, VPs, market intelligence managers

- Procuring and national sales managers technical personnel, distributors and resellers

- Research analysts and key opinion leaders from various domains

Key Points Covered in Metal 3D Printing Market Study:

- Growth of Metal 3D Printing in 2022

- Market Estimates and Forecasts (2017-2030)

- Brand Share and Market Share Analysis

- Key Drivers and Restraints Shaping Market Growth

- Segment-wise, Country-wise, and Region-wise Analysis

- Competition Mapping and Benchmarking

- Recommendation on Key Winning Strategies

- COVID-19 Impact on Demand for Metal 3D Printing and How to Navigate

- Key Product Innovations and Regulatory Climate

- Metal 3D Printing Consumption Analysis

- Metal 3D Printing Production Analysis

- Metal 3D Printing and Management